Craftsmanship, passion and expertise is what we mean when we talk about bespoke shoes. An ancient craft which for a long time, has made Italy a world landmark.

Bespoke shoes: the invaluable handmade form

The history of bespoke shoes dates back to centuries ago when humans began to travel the world and were in need footwear that made their journeys more comfortable. Gradually over time, shoes have now become a sign of social recognition. And with them, the craftsmanship has developed from simple manual work, to real, true art.

Not to mention that years ago, the “use and then throw out” ideology didn’t exist: few people had two pairs of shoes and it was customary for them to be passed around from brother to brother, and then eventually taken to the cobbler for repair. The workshops then became a meeting place where you could chat while the villagers waited in line for their turn, with their shoes in hand. The shoemakers started work at dawn and finished late at night, accompanied by the dim light of an oil lamp. The tools they used the most to produce bespoke shoes were: an awl to pierce the leather and hide, a hammer for hammering and prying out the nails, a rasp to cut out the sole, a moulder, a knife, pincer grips and a crowbar.

In Italy, in particular, the great ability of our craftsmen to produce bespoke footwear has meant that our country is recognised around the world for the high quality of handmade shoes, and using quality materials. It’s still a fascinating craft because there are not many workshops where shoes are handmade and bespoke. And the form of the shoes is very important because it follows all the production stages of the shoe; from choosing the most suitable materials, to the model to be made, right up to the packaging.

Bespoke shoes: the stages of handcraftsmanship

As soon as they are shaped according to the specific requirements of the person, the bespoke shoes are already very personal. That’s why each stage of production must be carefully studied and adjusted according to customer’s requirements.

The first step is to create the shape from a “silhouette” made of standard wood which is modelled using measurements taken (length, circumference, circumference under the neck, circumference of the neck, foot entrance or where it will sit).

The second step to producing handmade bespoke shoes is creating the shoe upper: from the shape measurements, a paper template is prepared, which is then used to cut the leather. After cutting the leather, the various pieces making the upper are combined with the stitched lining. This process is called splicing. Eventually, the shoe is pre-assembled, namely the temporary shoe frame is joined to the mould with tacks. The bottom of the handmade shoes consists of the sole, insole, levelling (a thin layer of leather or cork is placed in between), the welt (a strip of leather or stitched rubber reinforcement between the sole and the upper), and the upper and lower heel.

The assembly procedures are:

- The frame, that is, the adjustment of the upper on the mould;

- The insertion of the sole, which is the final stamping of the upper done by inserting the shank between the heel and the underneath;

- The stitching of the welt, which is the soft leather strip that holds the seams together, ensuring waterproofness;

- The application of the sole, which is the process in which a rubber glue is spread along the outer edge of the shoe, to which the sole is then applied;

- The construction of the heel which is done using various layers of leather, which are fixed one after the other to the rear part of the sole and finally moulded to obtain the desired profile.

The finishing phase of the bespoke shoes consists of three final stages: a bottom coating which consists of painting the bottom with aniline colours that must be left to dry for around 1 hour, grinding and polishing, and finally the mould release.

After ten days from these last stages, the handcrafted shoe can be removed from the wooden structure and finally cleaned by manual polishing of the upper and the bottom.

The perfect types of leather for bespoke shoes

If you decide to opt for bespoke shoes, it’s important to be aware of the types of leather which are most suitable for your order.

The leather for bespoke footwear consists of two sheets: the crust, which is the skin from the flesh side and a top layer, which is the part of the skin from the hair side. Cowhide is the most widespread and commonly used; its thickness can vary, and it is available in different colours and weaves. It is the most commonly used for handcrafted men/women shoes which need to have a certain rigidity.

The cowhide leather is mainly used for small leather items and is characterised by its distinctive colour: it tends to become lighter over time.

One of the most valuable leathers is chamois leather, and from this comes the term “suede“. This type of leather is the result of complex and articulated production: you have to work the crust of the hides with direct scraping and subsequently subjecting it to oxidation tanning, in which fish oils are used.

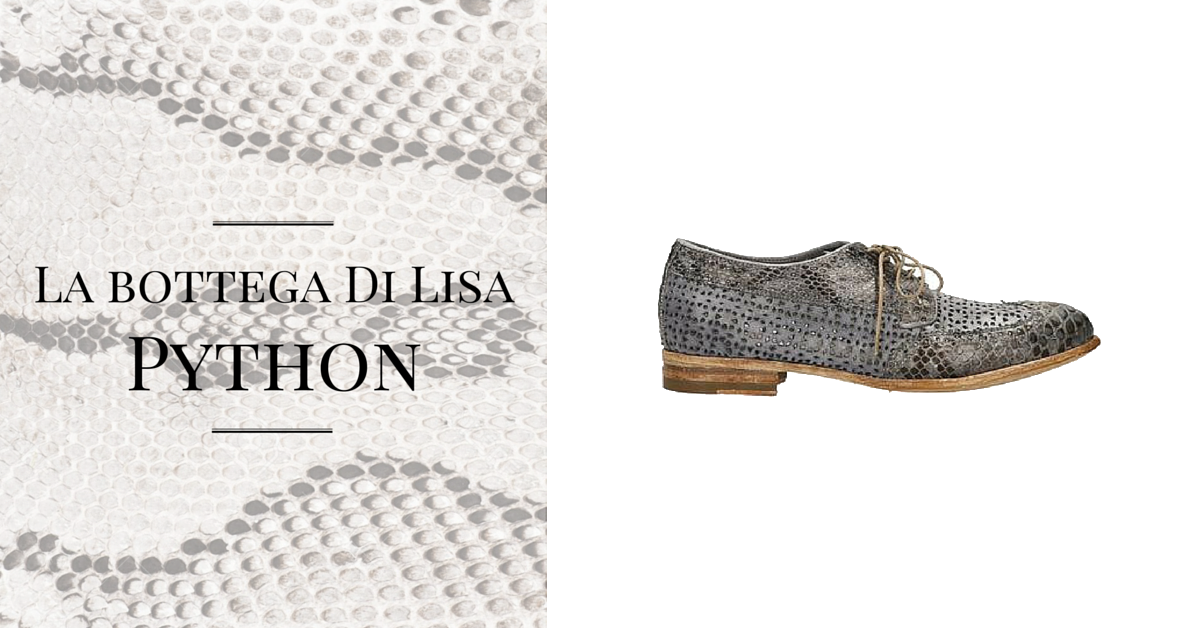

Especially for use in the production of bespoke shoes, is python skin. Its charm lies in its uniqueness: All leathers are different, because the grafting is variable. The scales which are lifted may reflect delicate and fragile skin, but can actually conceal a very tough leather which is easy to work on, so it is adapted to the creation of many products.

Finally, crocodile skin is also a very special choice for bespoke footwear. The reptile’s belly is the most valuable part and is usually (combined with the hips) used to make the finest creations. This leather, because of its scaly nature, requires specific perforating tools, such as special needles for sewing machines.

Would you like to have your own bespoke shoes? Visit our website and discover all the creations of the Shusala artisans: strictly handmade, following the ancient tradition of a process that has been passed down for generations. In just 14 days to your front door. Are you still here?

No Comments

Sorry, the comment form is closed at this time.